Description

Housing: Impact resistant, high flame resistant, light grey Polycarbonate (PC)

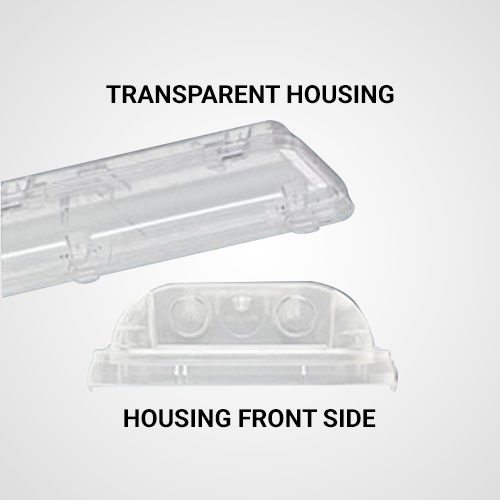

Optional: Transparent Housing (TH). Non ageing Polyurethane foam gasket. Integrated self-pollock clipping system.

Reflector: In galvanized rolled rigid sheet steel, with rounded profile to eliminate sharp edges. On request a flux regenerator reflector can be added and its made of high gloss aluminum anodized curved sheet 99.8%.

Painting: In several stages, starts with phosphating then chromating, drying then stove epoxy powder enameling cationic anionic (electrostatic) (RAL colors upon request).

Diffuser: A. Injection molded (one piece extruded) impact resistant, UV stabilized polycarbonate smooth surface with clear prismatic structure.

- Injection molded Plexiglas PMMA diffuser smooth surface with clear prismatic structure.

Lamp Holder: Polycarbonate with phosphorous bronze contacts.

Electrical Gear: 220-240V/50HZ

Power Supply: Hard wire, heat resistant (up to 150 °C).

Optional: HPF, Digital, Dimmable, DALI Electronic, Emergency Conversion Kits and all types of Emergency modules, And addressable sensors.

Equipment: Rubber cable gland & grommet in separate bag and optional mounting stainless steel brackets are supplied for suspension purpose.

Regulations: Manufactured in accordance with EN60598- CEI 3421 standards. Degree of protection in accordance with EN60529 standards.

Applications: Industrial facilities, assembly bays and areas, underground garages and multistory car parks, Utility rooms.

Options:

- Radio interference suppression.

- Specular Aluminum reflector optic symmetrical or Asymmetrical.

- Fused terminal block.

- Fitted on all types of BusBar Trunking systems with plugs and clips singular or in groups.